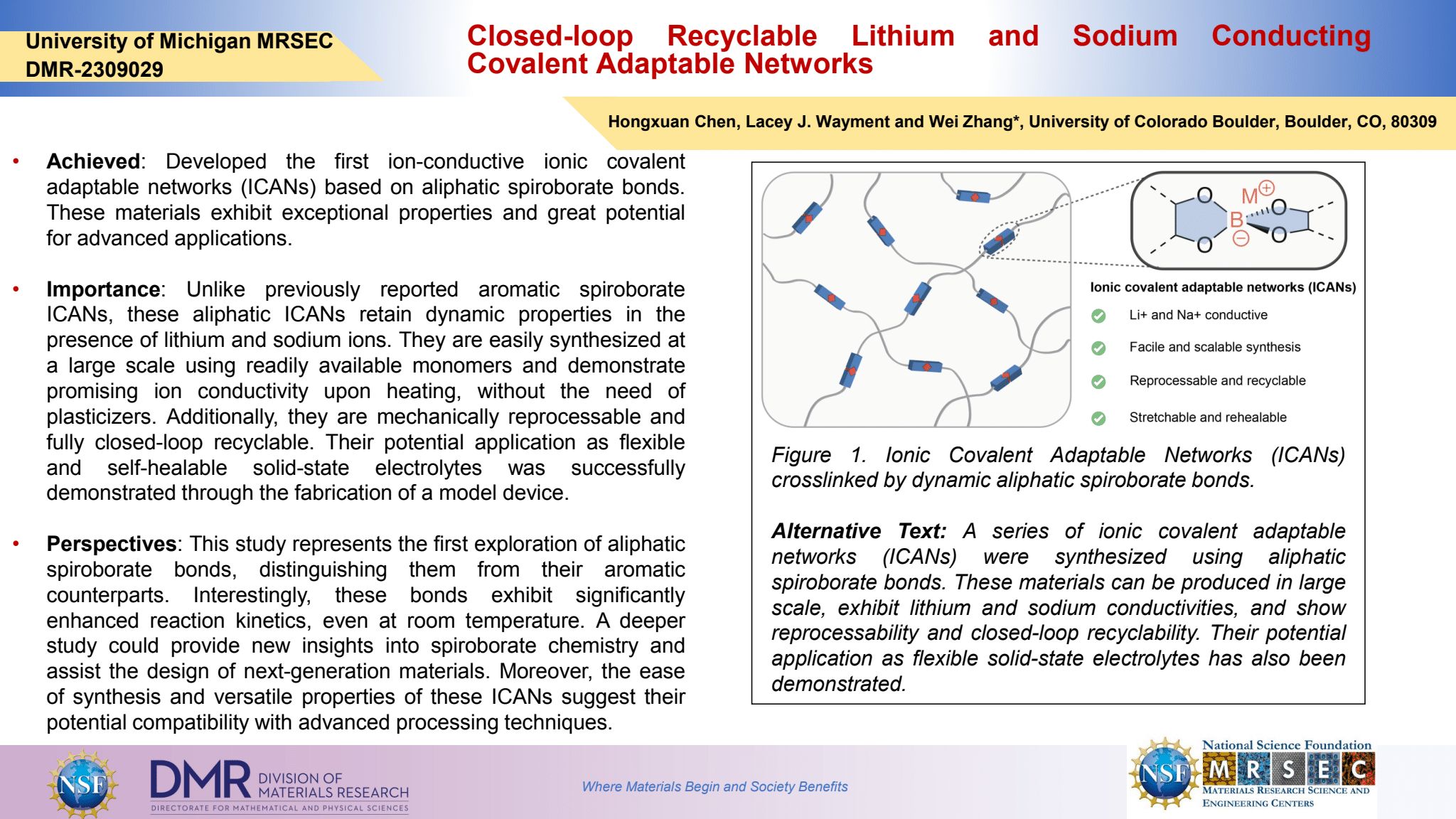

First examples of small molecules and ICANs based on aliphatic spiroborate bonds have been reported. The model reaction kinetics were determined. Thermal, mechanical properties and ion conductivities of ICANs are determined. Their potential application as flexible and self-healable solid-state electrolytes was demonstrated.

Compared to the aromatic counterparts, aliphatic spiroborate exhibit unexpectedly enhanced reaction kinetics. The multi-ol monomers can be synthesized from commercially available epoxide precursors through a one-step hydrolysis without complicated purification. One of the precursors can be produced from bio-source, further enhancing the sustainability. The ICANs can be rapidly reprocessed via heat press at 90 °C within a few minutes, and can be closed-loop recycled to monomers under moderate conditions. Additionally, in the square wave experiment, the fabricated ICAN-based device can retain the electrical current under extreme physical deformation. Moreover, the broken device can be rapidly healed by wetting it with methanol and applying gentle heat and pressure. The electrical current can be resumed within minutes, highlighting their great potentials in applications as flexible and rehealable solid-state electrolytes.

Previously computational studies indicate sodium or lithium counter cations can raise the energy of transition-states, thus prohibiting the spiroborate exchange reaction. However, this study confirms that this conclusion does not apply to aliphatic systems, meaning that deeper mechanism study is necessary to fully understand the spiroborate chemistry. By cooperating with researchers from computational and modeling fields, the mechanism study can provide new insights into not only the fundamentals of spiroborate bond, but also guides the future direction of materials design. Additionally, these ICANs are highly flowable at higher temperature and their viscosity changes significantly upon temperature changes, making them potentially compatible with advanced processing techniques such as 3D printing and injection molding.

Published: Angew. Chem., Int. Ed. 2025, 64, e202425497. DOI: 10.1002/anie.202425497.

hi

hi