The research objective of IRG 2 is to design, synthesize, and utilize fully reversible, dynamically reconfigurable polymeric materials that facilitate processing, functionality, self-healing, and recycling with unprecedented versatility. We are developing a relatively new class of reconfigurable covalently bonded polymeric materials that have reduced environmental impact, the potential to revolutionize the polymer manufacturing and composite industries, and the ability to facilitate new socio-economical initiatives from agile manufacturing to energy preservation to space exploration.

Organic polymeric materials are presently used extensively in construction, automobiles, textiles, and medical applications, with 390 M metric tons produced annually and an expected growing demand for the foreseeable future. A majority of discarded plastics are presently burned, stored in landfills, or pollute waterways, oceans, and the air. The incorporation of crosslinker molecules in polymers that form reversible dynamic covalent bonds between chains that can break and reform in response to stimuli such as temperature or light is a potent strategy to increase the recyclability of plastics. Such covalent adaptable network (CAN) polymers have tremendous potential for materials design and discovery. The realization of fully recyclable plastics with tailored and optimal physical, thermal, and chemical properties requires mapping this design space.

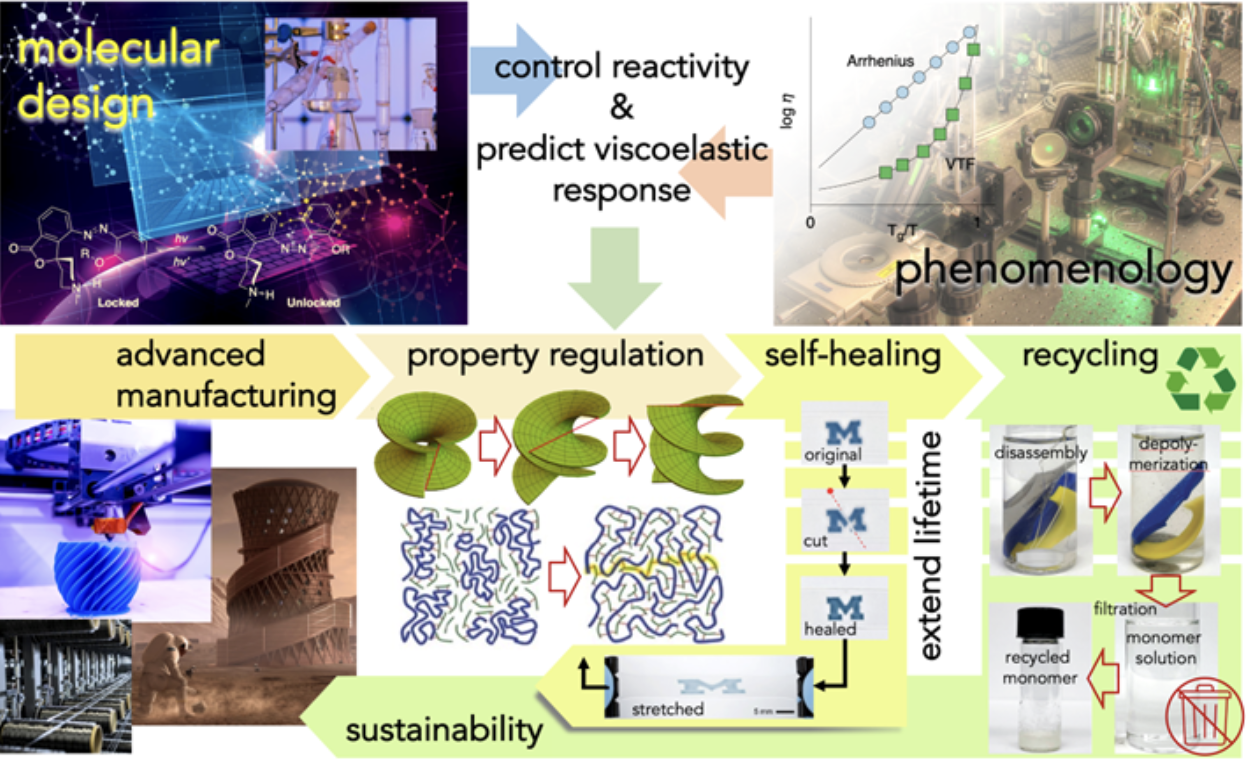

The work in this IRG has 3 primary goals. (1) To render existing technologies more sustainable through new inherently recyclable CAN materials to replace both thermoplastic and thermoset polymers. We establish accurate phenomenological models that account for how structure and extended-range molecular motion affect the crosslinking reaction pathways through refinements in viscoelasticity theory. (2) We enable advanced on-demand manufacturing processes and novel structural designs. We investigate the interfacial welding and reshaping dynamics of CAN-based materials to explore their potential for manufacturing under extreme conditions. (3) We devise customized adaptable materials whose properties can be regulated with precision and during operation. We are exploiting unique classes of thin elastic bodies, e.g., minimal surface associate families that allow for locally actuated global 3D shape morphing via a single displacement mode. Using CAN functionality, such shapes can be locked into rigid, load-bearing structures and, when needed, controllably actuated through stimulation.

To realize these goals, this IRG aligns with the DMR Industries of Tomorrow paradigm for materials discovery and the NSF strategic areas of interest in Advanced Manufacturing, Materials under Extreme Conditions, and Sustainability. The workflow integrates simulation, experiment, and data sharing and reuse (open-access, searchable databases per FAIR principles). These efforts contribute to the development of highly skilled, diverse, and equitably recruited scientists and engineers.

hi

hi